OK, I’ve been away from replies to this for a few days because of personal matters. so now I’ll catch up with this.

I described my particular case as a CHURCH ORGANIST… Now then, If you’re familiar with or ever seen a church organ, there’s 2 concepts of design. They are Draw Stops (hence pulling out all the stops) which is the original design of not only church organs, but early pump organs and reed organs in stately homes, etc. The second design is known as Tab Stops. Over the years, they’ve changed in design concept from front facing tab stops with either hydraulic, latch coupling or electro-magnetic actions, Tongue profile tab switches which are electro-magnetic action, or today’s new standard which are “Momentary Rocker” tab switches which have no mechanical recall, just an LED set behind the tab as a semi-opaque plastic with the function name etched to the centre of the tab. There is also what’s called a “Soft” Draw stop. This design is a cheap version of an electro-mechanical or Electro-Hydraulic or even Vacuum Hydraulic stop, however, thisdoes not have any form of physical actuator to recall physical position, it is just a momentary switch reverse set, so that when the stop is lightly pulled out and sprung returned, it will either switch on or off, the stop has an LED through a tube in the centre of the stop body where a semi opaque dome finish face is inscribed with the stop, coupler or function.

As previously discussed and my attempts to make this clear. An organ console layout covers multiple keyboards “Manuals” as well as the pedalboard, so, these are divisions, an average church organ spec / cathedral organ spec focuses on 4 or 5 divisions, they focus on Pedal, Solo, Choir, Great & Swell (5 division) or without the solo (4 division). Each division will include a quantity of stops (Voices) and depending on design of the console / maker) for the genuine pump blown consoles which were electrified from the 70’s onwards with complex hydraulic systems with controllers) a console would have a panel above manuals for couplers, tremulant or tremulants, particular functions such as tremulant speeds, etc. Under each manual, a set of Pistons, these are a combination of Divisional Pistons for each manual and depending on console design, also General Pistons which store the entire organ’s settings to recall.

Now, with this in mind of a mechanical action console (regardless of the mechanical specification used), when you recall using divisional pistons for a particular manual, that stored function then via a process control system instructs particular stops, couplers, etc to move to turn on or turn off. Even the General Cancel piston, this instructs the entire console to “Zero Out” aka, all off., so it returns the console to initial state ether when turning the console off ready for the next service, or when setting the console up for another series of stops.

A traditional console where either Draw or tab stops are fitted, is purely tactile, the only functions which don’t themselves have an instant recall due to their very nature, are divisional and general pistons, Gen Cancel, SET and sequencer functions, these are becahse they are purely momentary fnctions as instruction commands only to alter stop and coupler functions. For someone blind, like myself who sees nothing but Pure Black (that would frighten the hell out of anyone), touch is the most vital sense in processing multi-sensory information. For that of an organ, the issue is of when a stop is engaged / disengaged. Referring to the above states, a draw or tab stop console with any form of mechanical action with physical action drive (ability for a stop to be moved by mechanical recall) can be felt easily, But not if the console has “soft” tabs or “Soft” draw stops.

Picture if you will, yourself sat at an organ console, like a Fr. Willis & Sons, or Harrison & Harrison., where you are faced with 4 manuals directly in front of you, to the left you have a large panel in an angle of about 30 degree, this would contain approx 40 physical draw stops. They would be assigned in groups with a 30 degree 1 to 2 row difference in position (Row 1 is at top, row 2 drops down in line with the gap between the two stops distance of row 1), so you can feel where you are in a stop gallery. These concepts weren’t designed for the blind at all, these were designed as far back as the mid 1800’s for certain large format consoles. Each division has a difference in distance known as a split. sighted users will notice that each gallery has a name plat above each stop gallery indicating the division or function array. So, the left Stop Jamb would house the Pedal, solo and either full or half Choir. The right stop jamb described in similar terms would house either. half of the Choir, then Great and Swell divisions, also any Couplers or assignable functions for unique stops which could be routed to different manuals independently… Above the top manual (Swell) you would likely find a panel with a series of front facing tab stops, these are actually a number of function states, not voices or ranks, these would be Couplers, Couplers link manuals to manuals or manuals to pedals. good example, Coupler saying “Pedal to Great” means that when the pedal board is connected to the great, both pedal division stops and Great stops are played by the pedalboard, to Wind blown consoles this comes at the cost of being a Tracker action / Hydraulic action series of keyboards, what this means is, it’s not a simulation, you press a pedal note such as 1st octave D, then the First octagve D of the Great manual is also physically pressed by the pedal. or if you coupled the choir to swell, pressed several keys of the choir, the exact same keys of the swell are also played by physical coupling. Electronic / Digital organs don’t do this, because it’s reliant on electronic instruction such as MIDI, general digital keyboards / manuals don’t have a mechanical coupler action, they are tracker emulation by weight and physical feel of the keys, but not by the purpose of physical coupling. The coupling is digital / electronic and as such means it’s “Virtual” so the coupled keyboard doesn’t physically move, but the sound engine replicates by receiving the midi / CV message and plays the coupled manual’s sound board. Still provides the same basic function, but from an aesthetic principle, doesn’t quite resemble that of a traditional console. To do that means electro=mechanical UHT keyboards which are hellishly expensive, further power raills, etc.

Each manual will have underneath, a series of pistons, as discussed, these are either General Pistons or divisional pistons. there may also be dependent on the design / electrifications of the console, sequencer functions such as SET and div cancel (divisional cancel per manual) or General Cancel to the lowest manual usually to the right.

Under the manuals, depending on console design, there may likely be “toe Studs” as well as expression pedals. Expressions cover 2 functions, Crescendo which turns on each stop as programmed by the organ builder in conjunction with an organist when commissioned, (when the crescendo is off - showing up - then any of the stops pulled out for each manual are in use, as the pedal is pressed to move down, further stops are added to each division to expand the sound, to near a full “TUTTI”, when brought back to "off state, the previous stops are back to their state) Consoles are designed differently depending on needs at the time of installation / commission including what expression pedals are added, such as Swell, Choir, Solo, these operate louvre panels within the pipe galleries to enclose (soften) particular divisions, or to open out and let the particular galleries speak out, which is part of the performance of a pipe organ, same goes for a digital console / hauptwerk system, etc. Toe studs are functional pistons either as divisional pistons for the pedal, couplers for pedal, sequencer, etc. For a blind person they’re an interesting experience as you’ll hear now lol.

As an organist, if I turn up at a church I’m booked for, it’s a new console I’ve not worked with before, I have to feel my way around the console. the hardest challenge is knowing what stops are available, couplers, etc. so it boils to two things, either A: if there’s someone there sighted who can provide a read out of each function, they don’t have to understand them just speak out as I then remember the functions, or if engraved, I feel them. now, here’s the laugh of it. Toe Studs… As the name suggests they are at the bottom, away from the pedal board, about 8" away from the raised flat / sharp keys, either side of the expression pedals. Either I run the console and explore it that way, or if there isn’t time, then, I do this… balance myself so that my stomach is on the organ bench, so you basically notice a “bum” in the air, maybe feet also. and my hands feeling positions of toe studs and feeling the inscriptions if there are any. This happened at a cathedral I started working with many years ago, the Priest who only just got to know me, didn’t understand blindness, nor have a single clue of how to support me, so I had to educate him, officially. I was unaware of the fact he was in the building until I heard footsteps closer and closer, as I’m actually doing this very act, this was the first day of my appointment so needed to know the console inside out and couldn’t find someone to be my eyes. “Good heans, What is it that you’re doing?! How unbecoming of someone!”. So, I slid back, turned my head in the sound of his direction. “Sorry Father, just touching up the organ.” “Don’t worry, I’m trying to ascertain what toe studs are what functions, new console to me.”

He didn’t understand until he saw the white cane on the floor. then explained that I am fully blind, seeing nothing but black, this is a new console build to me compared to where I usually work and I need to know what functions are available to me to really make this console sing… So, after that, he stood there as I went through the start of a stop list for notes, then once I found my feet, went through a performance, bringing the console to TUTTI slowly and stunned him, he never had an organist as daring as me.

Now then, back to my point. I’ve described this to you to picture in your mind, the physical layout of a console, now think of yourself surrounded by absolute black, you can’t escape it. Then think “How do I play this organ, I don’t know where the stops are, pistons, etc.” It’s all by feel, the best interaction possible. takes time to learn playing a piano or organ blind, it’s not just the sound, it’s the tactile response and engagement.

All this talk of vibra-capacitive switches, etc, isn’t a source of help inn design. switches like these don’t help in a console design. Why, Think of the stop layout, think of a console with total of over 100 physical stops spread over 2 jambs (left and right). To do this using these switches means that each stop you’d have to rest your finger on to rely on a pulse to state active / inactive, do that over 100 stops, you’d be absolutely confused as heck. Lit switches are fine for someone with sight impairment as they still have light dependency, I don’t.

There are two viable solutions which are viable. this comes from me in a professional capacity as well as that of a blind person and musician, so I’m saying it clearly and happily, with pride.

Solution 1: a hard-wired set of jambs with tactile switches with a physical recall, when the switch is in (pressed in) it’s off, like a normal console would be. when the switch is raised, it’s on. so a square or round momentary type but would need solenoids to drive the buttons to raise / lower for stop recall. I have spent a lot of time trying to find such a solution without luck.

2: Custom Control Surface via Yaeltex. System is fully programmable and designable to particular requirements. Large buttons of different designs can be used. Limitations of the design are that the buttons are lit buttons and “soft” buttons, but they are programmable RGB for sight impaired users and light can be disabled to my understanding if a function is off, so a light scanning tool could be used. The other way of light translation is temperature based, no fancy tools, just how your skin responds to surface temperature and change of, your skin also responds to light as light emits radiation in various levels, so the skin translates this, to some people, it’s a good response. for a blind user, this would rely on adaptation of the host software to speak a function enable, etc and rely on tactile memory when using the system

3: Touch Screen Operation. Touch screens are being used by the blind community through products based on Android, Linux and MacOS, as well as Windows. Screen reader systems are developed now to support touch screen technologies. Take a look at your Apple iPhone or iPad as an example. VoiceOver is actually embedded into the OS by default and ready to use. it adds a touch layer to the OS fundementals and as such adds further functions for the blind. A sighted user just presses once for an app to open or a function to activate / deactivate, single finger glide to change a parameter value such as a slider / rotor, etc. for a screen reader to provide the degree of accessibility to a touch environment means a layer addition and change of gestures. so, an example you want to know where your finger is on a touch screen, press once while the screen reader is running and it will inform you if you are on an app, parameter, text entry, etc, if there’s nothing there directly under your finger, a small sound effect plays, depending on configuration state of the screen reader’s parameters. to engage, such as to turn a function on / off or launch an app, you double tap. it announces the state or opening of a function / app, etc. there are various gestures which are spoken to provide such parameter changes.

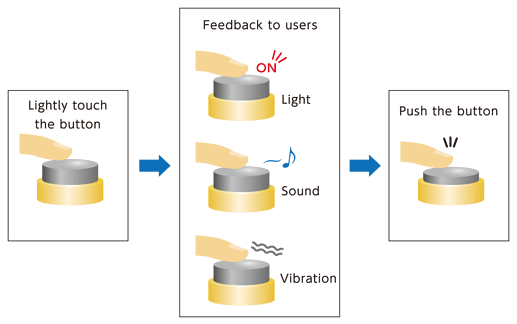

Now then, These 3 systems are all perfectly viable. and have their strengths and weaknesses. Option 1 does not require any form of screen reader functionality as it’s purely tactile and that’s the most vital. using anything like a vibrative button interface causes delays in translating what’s there and instant confusion. you want to glide your fingers across or down a surface and know a button is raised or not, not have to rely on a delay action vibration, etc when you’re running multiple stops per manual.

Touch screen interaction will require the host OS with the computer such as a Pi or NUC / USFF system running the OS in question and it’s products in conjunction with either a screen reader running and a series of optimisations of the app in question, or a speech UI that works in the same basic function of the screen reader, but is just purely focused on button engagement / disengagement. This works great with a touch screen based environment as confirmation of such details is there. A script could be created to give a running list of stops engaged, such as “GREAT: Plenim 8’, Bourdon 16’ etc ON” that would be more than enough to provide a great level of accessibility. all that takes is a few seconds of speech out, to the system output of the SBC (computer host) to an earbud. simple as that.

lew