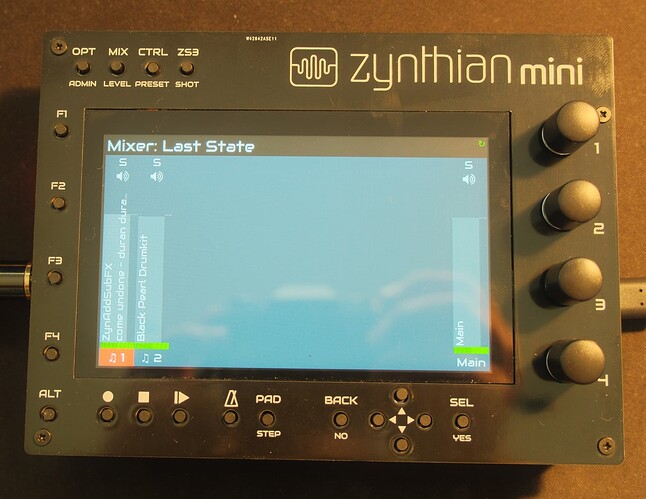

Here is the latest report on Mini PCB and PCB facia that I have tested this weekend.

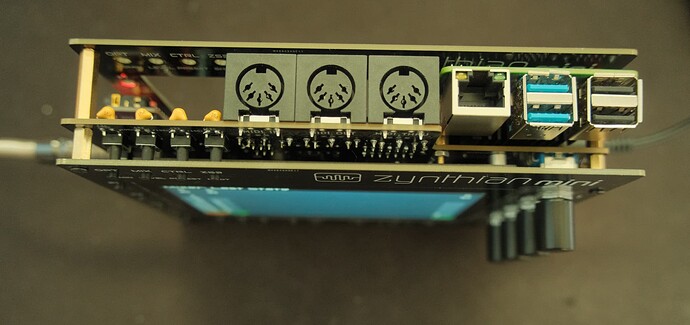

Main PCB is fully functional and no issue with it at all. It just takes few hours to solder everything together.

PCB facia works nicely but it can be further improved.

- push button holes can be with smaller radius. I used the same radius that I use for 3d printed case but holes on PCB facia are produced with much better precision so there is no need for such a big tolerance.

- KiCad PCB facia design have front and back swapped. This is because I simple copied main PCB design when making PCB facia so that dimensions are kept the same. This means that order number that is typically printed on the back by production companies now appears on the front. You can spot it on the top of the PCB facia.

- it would be good to have connector labels on the front as they are on V5. I will include connector labels into 3d printed enclosure design but it would be nicer to have them on the top facia and simplify printing process. Any volunteers to help me there?

I will work on these facia improvements but if you want to order PCB as it is here is the link to my pcbway orders. I am getting 10% of every order which is almost enough to buy me a coffee.